Particulate Filtration Systems

Brief Description

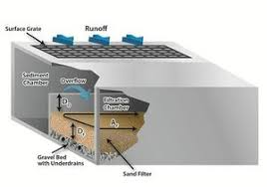

Particulate filtration devices allow stormwater to pass through filter media which are designed to reduce specific stormwater pollutants, but primarily solids, nutrients, and oils. Pollutants are captured physically or through absorption onto the filter media. Filters may be inserts that are retrofitted into existing catch basins or manholes, stand alone proprietary units supplied by a manufacturer, or individually designed and constructed units. Typically suited for locations where infiltration is not an option.

Cost Range

Construction: $$$

O&M: $$$

Ideal Conditions for Installation

Precipitation: (typically designed for 90% storm or storms up to 2 year event)

Soils: (Sandy, silty or clayey soils)

Groundwater: (1-3 feet below the bottom of filter system)

Where/Applicability

Residential: Yes

Commercial: Yes

Ultra Urban: Yes

Industrial: Yes

Highway/Road: Yes

Retrofit: Yes

Maintenance

Frequency:

- With pretreatement: 4-5 years

- With no pretreatment: annually

Type: Vac. Truck, Filter media replacement, Jetting, Filter media back washing

Monitoring: Inspected annually

Permit Renewal: Varies by permit

Performance

Total Suspended Solids (TSS): High

Chloride: Medium/High depending on media

Total Nitrogen (TN): Low/Medium/High depending on media

Metals: Low/Medium/High depending on media

Oils and Grease: Medium

Pathogens: Low/Medium/High depending on oxygen in filter media

Specifications

Pretreatment is recommended to remove sediments and floatables.

1. Follow the manufacturer recommended requirements for installation, operation and maintenance.

2. Include inspection and maintenance ports to make it easy to inspect and maintain the filtration device.

3. Select filter material designed to drain within 24 hours.

4. Filter cloth should be woven geotextile with a hydraulic flow rate of at least 100 gpm/ft^2.

5. Liner material should be a minimum of 20 ml poly.

6. Gravel should be clean/washed with no more than 5% fines.

7. Limestone aggregate is not acceptable.

Construction Sequence

1. Install pretreatment device.

2. Install liner if contaminated soils underlying the site.

3. Install main structure (if proprietary) and then filter media.

4. Install initial base course of gravel or filter media.

5. Install pipe network of chambers and interconnecting pipes.

6. Install remaining gravel and filter media.

7. Cover entire area with filter cloth.

8. Install necessary ground cover (pavement, top soil and seed)

Downloads

Stormwater Management Solutions

https://www.conteches.com/stormwater-management

Kraken Filter

https://biocleanenvironmental.com/kraken-filter/

Armtec Stormwater Chambers

https://armtec.com/products/stormwater-management/retention-and-detention/

Links

Contech Case Studies Reference

https://www.conteches.com/knowledge-center/case-studies/search?filter=0DKG10DMD4

Minnesota Pollution Control Agency Reference

https://www.pca.state.mn.us/water/stormwater-management

EPA BMPs for Stormwater Reference

https://www.epa.gov/npdes/national-menu-best-management-practices-bmps-stormwater#edu